90% White Metal Bearings |

|

|

| Performance

Benefits:

.

Lowers Lub. Oil Consumption

. Maintains

specified fuel Consumption for longer service

. Can

be used against hardened as well as unhardened shaft

. Protects

shaft from extensive damage

|

Special Features:

. Reduces operating cost Considerably.

. Lined with Genuine Tin Base 90% While Metal

. Retains Lubricants

. Embeds dust and debris carried by the Lubricant and prevents scoring at high loads

. Highly compatible to avoid seizure

. Conforms to misperfection in Shaft geometry

. High Strength to resist deformation by both steady & fluctuating loads

. Resists corrosion by lubricants

. Good thermal conductor, dissipates heat faster from the mating surface and runs cool

. Excellent resistance to wear under conditions imposed in journal |

Copper-Lead

Bimetal Bearings & Bushes (CUPB) |

|

|

Copper Powder Metallurgy for Bearings:

. Copper readily

forms a protective oxide film when heated in air.

. Copper readily

forms a protective sulphide film with oils containing only traces

of sulphur compounds.

. Copper has

a high thermal conductivity for the dissipation of the frictional heat,

thus reducing the surface temperature.

. Tin strengthens

copper and hardens it sufficiently to be compatible

with unhardened steel.

. The protective

Organo-tin films formed with oils have a high

desorption temperature

. Hence the

copper-tin bronzes result in better bearings than the

copper-zinc brasses.

. Copper alloys

usually have a face-centered-cubic structure while the

mating surface is usually a ferrous alloy

with a body-centered-cubic structure.

This difference

contributes to the anti-seizure characteristics of copper

alloys

against iron alloys.

Overlay

Plated Copper-Lead Bearings for Heavy Duty Service:

. The Copper-Lead

Bearings when plated have higher load carrying capacity

than straight copper-lead alloys.

. These overlays

are very soft and have excellent embeddability,

conformability and corrosion resistance without impairing

higher fatigue

strength of inner copper-lead-tin alloy.

|

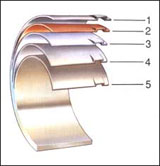

Different Layers in typical overlay plated bearing

are as under:

. The

steel backing to give the bearing

strength and regidity.

. The

copper-lead-tin intermediate, alloy lining

is permanently bonded to the steel back by

intering process. It is the lining alloy that

will stand up under extreme bearing loads.

. A nickel

plate or nickel barrier - just 2-3

microns thick - preventing the tin

|

from overplate alloy from being

drawn into copper-lead alloy lining.

. The

lead-tin-copper plate that easily confirms to slight

irregularities

in the crankshaft journals during engine run-in.

. The

pure tin flash plate which provides corrosion and rust

resistance all over.

|

|

|

>

Engine Bearing &

Bushes

>

Lubricants

>

Quality

Control

|